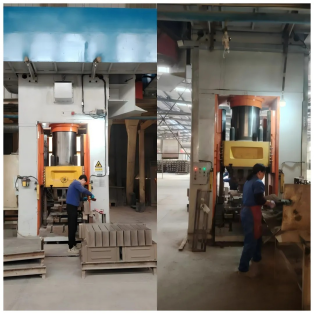

To achieve success in one's work, one must first sharpen one's tools. The refractory materials base has always focused on the renewal, replacement, and transformational upgrading of production equipment, strongly promoting the improvement of production efficiency and product quality. Recently, the 15 newly purchased 630-ton electrically controlled spiral forming presses, which required a substantial investment, have begun installation and partial operation, adding new powerful equipment for the company's high-quality development.

The new 630-ton electrically controlled spiral forming press, determined after extensive research by the group, has been significantly improved compared to the currently used presses. It features high production efficiency, good forming quality, environmental friendliness, low operating noise, low consumption of lubricating oil and related spare parts, and low usage costs, making it another mainstay of the forming equipment.

As one of the top 100 refractory materials enterprises in China, Minmetals East Group has always regarded the renewal and transformation of production equipment as one of the important means to enhance the company's core competitiveness and build a leading brand in the industry. Through a series of automated, intelligent, and green renewal and transformation upgrades, the company's equipment level has been rapidly improved. Especially in the forming equipment aspect, the company has a large-scale, comprehensive-tonnage, and high-performance press cluster. The addition of the 630-ton electrically controlled spiral forming press has further strengthened the company's forming equipment.